Products

FPC P1.00 SMT upright drawer type

Key words:

Classification:

Detail description

1. Scope of application:

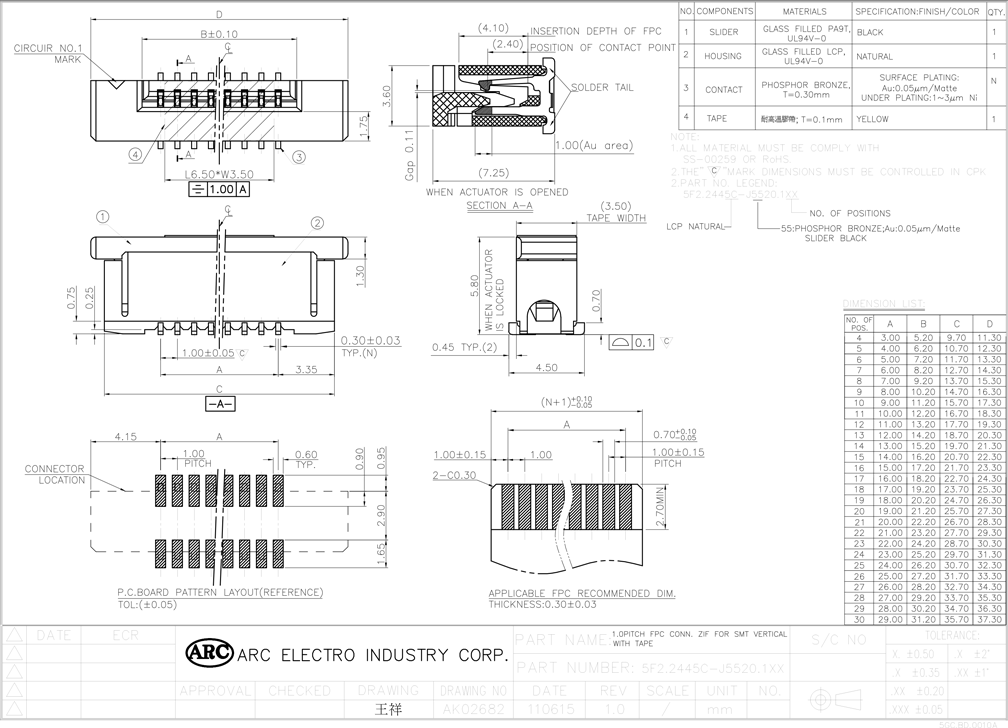

This job specification is suitable for: 1.0mm PITCH FPC CONN. ZIF FOR SMT VERTICAL

Connection with FPC: ZIF

FPC suitable thickness: 0.3±0.03mm

2. Related specifications:

EIA-364 : Test Procedures for Electronic Connectors and Connectors

UL STD-94: Specifications for testing the flame retardancy of plastic equipment parts and equipment.

3. Construction, dimensions, materials

See block diagram.

4.Standard status:

1) Rated voltage: AC/DC 125V

2) Rated current: 1A

3) Temperature and humidity range:

Operating temperature range: -30°C~+85°C; storage temperature range: -40°C~+90°C; storage humidity range: relative humidity below 90%RH

5. Performance

5.1 Structure

|

|

project |

Test Methods |

Specifications |

|

1 |

Exterior |

visual inspection, size measurement |

Meet the drawing requirements |

5.2 Electrical properties

|

|

project |

Test Methods |

Specifications |

|

1 |

contact resistance |

Test on the same terminal, short-circuit current: 10mA, open voltage: below 20mV, use wire: adapt to FFC standard wire. |

20mΩ Max . |

|

2 |

Insulation resistance |

DC 500V between adjacent terminals, 1 minute. |

100MΩ Min. |

|

3 |

Pressure test |

AC 500V between adjacent terminals, 1 minute. |

No breakdown, no short circuit |

|

4 |

The temperature rises |

Measure the temperature rise of the terminal when the terminal is operated at the rated voltage and current |

30℃ Max. |

5.3 Mechanical properties

|

|

project |

Test Methods |

Specifications |

|

1 |

FFC/FPC holding force |

After the FFC is inserted into the FPC connector, it is pulled out vertically at a constant speed of 25~100mm/min. After this action is repeated three times, the measurement data is recorded for the fourth time. |

SEE "FFC/FPC Retention Force" |

|

2 |

Terminal retention |

Pull out the terminal vertically from the rubber core groove at a constant speed of 25~100mm/min |

500gf/terminal Min. |

|

3 |

Action force of SLIDER |

Insert the FFC wire into the main body and measure the insertion and extraction force of the SLIDER |

SEE "SLIDER Force" |

|

4 |

Plug Durability |

Do the following moves for 30 rounds: FPC insertion, SLIDER insertion, SLIDER extraction, FPC extraction |

Contact resistance 40mΩ Max . No deformation |

5.4 Durability

|

|

project |

Test Methods |

Specifications |

||||||||||||

|

1 |

Vibration resistance |

The terminals are connected in series with a current of 0.1A dc, amplitude 1.5mm, frequency 10-55-10Hz, X, Y, Z direction for 2 hours each, a total of 6 hours |

The contact impedance is less than twice the initial specification; Discontinuous conduction within 1μs; Appearance is normal |

||||||||||||

|

2 |

Impact resistance |

The terminals are connected in series with a current of 0.1A dc, the acceleration is 490m/s 2 , the X, Y, and Z directions are each 11ms, each 3 times, a total of 18 times |

|||||||||||||

|

3 |

cold resistance |

Storage time at -40±3℃ for 96H |

1. Contact resistance: 40mΩ Max. 2. Insulation resistance: 50 MΩ Min. 3. Withstanding voltage: no breakdown, short circuit 4. Appearance: no abnormality

|

||||||||||||

|

4 |

heat resistance |

The storage time is 96H in the temperature 85 ± 2 ℃ |

|||||||||||||

|

5 |

Moisture resistance |

Temperature 40±3℃; Humidity 90~95% RH, storage time 96H |

|||||||||||||

|

6 |

Salt spray test |

Temperature 35±2℃; salt water specific gravity 5±1% spray test 48H |

|||||||||||||

|

7 |

Thermal shock |

-55±3°C; 85±2°C for 30 minutes each, 5 cycles in total |

|||||||||||||

|

8 |

Tin Wetting |

Dipping tin temperature 245±5℃ (Sn: Lead Free); time 3 ± 0. 5S |

Eat tin full, more than 95% |

||||||||||||

|

9 |

Reflow heat resistance |

Preheating time: 150℃ 80s, 180℃~230℃ 40s, MAX 230℃~240℃ 25s, do it twice |

The main body of the product has no deformation and blistering, and the flatness of the tin pin and the ground plate of the product is 0.10mm Max. |

||||||||||||

|

10 |

Sulfur resistance (gold-plated product) |

Meet the requirements of the test of three mixed gases

|

The contact resistance is less than twice the initial value; there is no obvious corrosion near the contacts |

||||||||||||

|

11 |

WHISKER (tin-plated product) |

Insert FPC after reflow, place 500H, observe the length of WHISKER |

100um max |

Pre

FPC P0.50 SMT vertical

Related products

Message consultation