Products

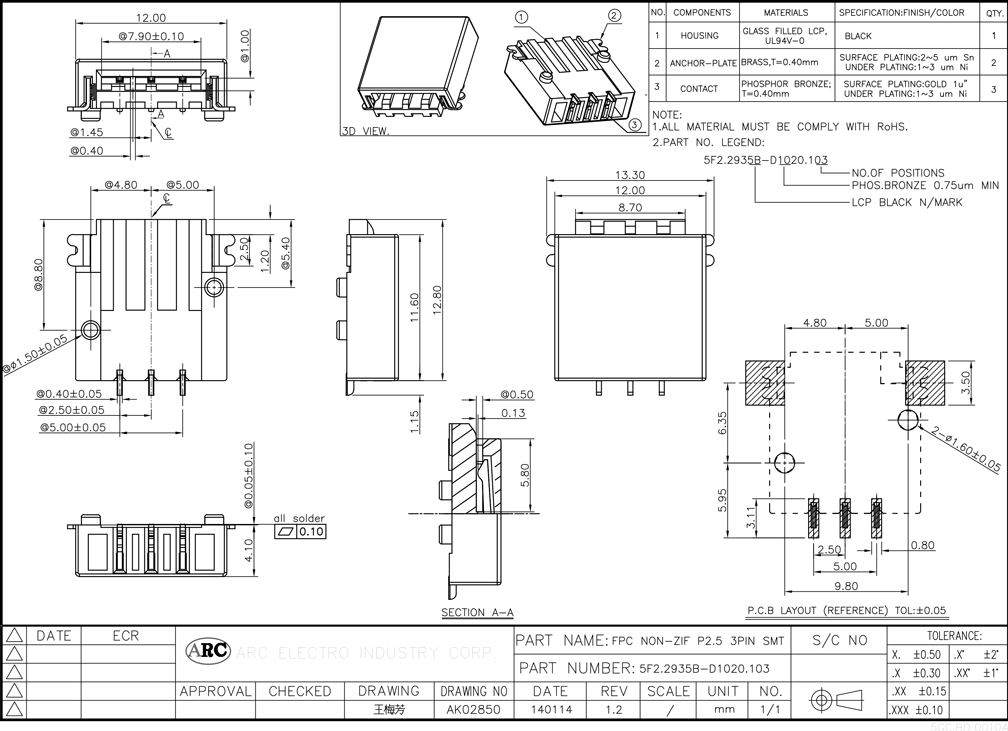

FPC P2.50mm SMT NON-ZIF 3P

Key words:

ARC

Classification:

Detail description

1 Scope:

This operation specification is only applicable to "Australia FPC 3pin NON-ZIF Pitch 2.50"

2. Reference documents:

The following documents are part of the specified specifications. If the requirements of the specifications conflict with the product drawings, the product drawings shall prevail. If the specifications conflict with the reference documents, the specifications shall prevail.

- UL STD-94: Specifications for testing the flame retardancy of plastic equipment parts and equipment.

B. EIA-364: Test procedure for electronic connectors and connectors.

3. Requirements:

3.1 Material composition:

|

|

part name |

Materials and Specifications |

|

1 |

main body |

LCP, black; |

|

2 |

terminal |

T0.40mm, C5191 bottom nickel plated 30u”Min, contact part gold plated 30u”Min; solder leg part gold plated G/F; |

|

3 |

Fixed sheet |

T0.30mm, C2680, bottom nickel plating 50u”Min, full tin plating 80u”~160u” |

3.2 Design and structure: The product design, structure and size are as shown in the product drawing.

3.3 Performance:

1) Voltage: 24V (AC, DC)

2) Current: 3.0A (AC, DC)

3) Temperature: Use temperature range: 5℃~75℃

Storage temperature range: -20℃~60℃

4) Test conditions:

This product is designed to meet electrical, mechanical and environmental performance requirements. As shown in the chart below

|

1. Product inspection |

||||||

|

project |

content |

terms |

Test conditions |

judgement standard |

||

|

1 |

product inspection |

Meet the company's drawings and specifications |

visually |

no damage |

||

|

2. Environmental Substance Inspection |

||||||

|

1 |

Test based on |

|

||||

|

2 |

judgement standard |

Environmental substances meet SONY SS-00259-technical specification requirements |

||||

|

3 |

Environmental substances Prohibited substances |

Heavy metals, organochlorine compounds, organobromine compounds, organotin compounds (tributyltin compounds, triphenyltin compounds), asbestos, azo compounds formaldehyde, polyvinyl chloride (PVC) and polyvinyl chloride compounds |

||||

|

3. Electrical characteristics |

||||||

|

project |

describe |

Test Conditions |

Require |

|||

|

1 |

contact resistance |

The same terminal test, current: 1mA; |

30mΩ MAX |

|||

|

2 |

Insulation resistance |

DC 500V between adjacent terminals, 1 minute; |

1000MΩ MIN |

|||

|

3 |

Pressure test |

AC 100V between adjacent terminals, 1 minute; |

No breakdown, no short circuit |

|||

|

4. Mechanical properties |

||||||

|

1 |

Pull out force |

Insert vertically at a constant speed at a speed of 12.5mm/min; |

0.4kgf MIN |

|||

|

2 |

Terminal retention |

At a speed of 12.5mm/min, pull out vertically at a constant speed; |

0.5kgf MIN. |

|||

|

3 |

retaining force |

At a speed of 12.5mm/min, pull out vertically at a constant speed; |

0.15kgf MIN. |

|||

|

3 |

Durability (fatigue) |

Insert the FFC cable into the main product and then pull it out, this action repeats 30Cycle; |

Appearance is normal Contact resistance: 40mΩ MAX Pull out force: 0.81kgf(8N) MIN No breakdown, no short circuit |

|||

|

5. Environmental performance |

||||||

|

1 |

Vibration resistance |

Amplitude 0.75mm, frequency 10-50Hz, X/Y/Z direction 2 hours each, 6 hours in total |

The contact impedance is less than twice the initial specification; Discontinuous conduction within 1μs; Appearance is normal |

|||

|

2 |

Impact resistance |

Acceleration 294m/s 2 , X, Y, Z direction each 11ms, 3 times each, 6 directions, 18 times in total; |

|

|||

|

3 |

Salt spray test |

Temperature 35±2℃; salt water specific gravity 5±1% spray test 48H; |

Contact resistance: 40mΩ MAX Insulation resistance: 1000MΩ MIN Withstanding voltage: no breakdown, short circuit Appearance: no abnormality |

|||

|

4 |

Moisture resistance |

Humidity 90~98% RH, temperature -10℃~+65℃ for a total of 168H, more than 7 times |

|

|||

|

5 |

Tin Wetting |

Dipping tin temperature 245±5℃ (Sn: Lead Free); time 5S; |

Wet tin area is more than 95% |

|||

|

6 |

Thermal shock |

-55°C±3°C; placed at 85°C±2°C for 30 minutes each, for a total of 5 cycles; room temperature 25°C |

1. Impedance: 40mΩ MAX 2. Impedance: 10MΩ MIN 3. Voltage: no breakdown, short circuit Appearance: no abnormality |

|||

|

7 |

steam aging |

Water vapor temperature 95°C, time 48H; |

|

|||

|

8 |

heat resistance |

The temperature is 85 ± 2 ℃ and the storage time is 96H; |

|

|||

|

9 |

IR furnace |

Preheating time: 150℃ for 80s, 180℃~230℃ for 40s, 230℃~240℃ 25s Soldering temperature 250℃; time 5+/- 1s |

The main body of the product has no deformation and blistering, and the coplanarity between the tin foot of the product and the fixed piece is 0.10mm MAX |

|||

Remarks: After the product is tested, it should meet the visual appearance requirements without damage, and must meet the additional requirements specified in Chapter 5 test sequence.

5. Product certification and re-certification sequence:

- Sample selection:

Sample selection should comply with the principle of randomness in accordance with the requirements of the structure column.

- Test sequence:

The following is an example of the detection sequence:

In test group A5

First test: 1. Product inspection;

Then perform the test: 2. High temperature life test;

Then execute the test: 3. Product inspection.

|

Test Certification Sequence |

Test items |

||||||||

|

A1 |

A2 |

A3 |

A4 |

A5 |

|

|

|

||

|

1 |

product inspection |

1,9 |

1,9 |

1,5 |

1,3 |

1,5 |

|

|

|

|

2 |

Contact Resistance Test |

2,7 |

|

2,4 |

|

2,4 |

|

|

|

|

3 |

Insulation resistance test |

|

3,7 |

|

|

|

|

|

|

|

4 |

Voltage withstand test |

|

4,8 |

|

|

|

|

|

|

|

5 |

Insertion force test |

3,8 |

|

|

|

|

|

|

|

|

6 |

fatigue test |

4 |

|

|

|

|

|

|

|

|

7 |

Salt spray test |

|

|

3 |

|

|

|

|

|

|

8 |

Temperature and Humidity Test |

|

6 |

|

|

|

|

|

|

|

9 |

Thermal shock |

|

5 |

|

|

|

|

|

|

|

10 |

Solderability |

|

|

|

2 |

|

|

|

|

|

11 |

Impact resistance |

5 |

|

|

|

|

|

|

|

|

12 |

Vibration resistance |

6 |

|

|

|

3 |

|

|

|

|

13 |

heat resistance |

|

|

|

|

|

|

|

|

|

14 |

current capacity |

|

2 |

|

|

|

|

|

|

|

|

Samples for each test |

1 |

1 |

1 |

1 |

1 |

|

|

|

illustrate:

- The principle of sample selection for test groups: refers to the comprehensiveness of samples in each specific test group. If each group of samples is a complete mold cavity, if the model number or serial number cannot be distinguished, it conforms to the principle of randomness;

- Principle of test group selection: test group grouping conforms to randomness, which means that 5 groups are randomly selected from several groups for testing;

- A1, A2, A3...A5 in the chart represent the serial number of the test group;

- In the chart, B1, B2, B3....B5 represent the quantity of each group of samples in the test group. When there is a model number or number, it means a complete model. When there is no model number or number, B1, B2... .B5 each group represents 5PCS samples.

6. Quality Assurance Regulations:

Unless otherwise specified, in the contract or procurement failure, we will abide by the quality submitted to the customer, and we will follow the controlled manufacturing process to ensure that the product meets the specification requirements, and the defective batch will be submitted for return or other corrections Measures. In addition, the component materials will not be replaced or changed. When there is a change, the materials used must be submitted to the customer for approval before implementation.

6.1 Secondary recognition inspection:

If there is a major change in the manufacturing process that affects the product form or function, etc., the product quality will be guaranteed. The re-certification test will be performed according to the test sequence of the component parts, and the product test will be re-certified according to the requirements of the development product quality and reliability engineering.

6.2 Quality requirements:

If there is a bad judgment due to improper equipment test settings or operation, samples can be sent for certification again.

When a product defect occurs, corrective measures should be taken and samples should be sent again, and corrective measures should be confirmed by testing before sending samples again.

6.3 Inspection data:

Inspection test data shall be recorded, evaluated, and used as evidence of the above items.

6.4 Quality test confirmation:

Applicable to ARC quality inspection, the sample, size and function requirements of the acceptable quality standard defined and used shall be tested in accordance with the applicable product drawings and specification requirements.

6.5 Shipping preparation:

All packaging should be fully protected to avoid damage to the product during transportation, thereby affecting the appearance and function of the product.

Pre

FPC P1.00 SMT upright drawer type

Related products

Message consultation